Insimbi engagqwali eqeda ukuthengiswa okuqondile kwefektri yekhwalithi

Izakhiwo Zomzimba

1. Kukhona ama-ion e-chloride endaweni yokusebenza.

Ama-ion e-chloride atholakala kusawoti, umjuluko, emanzini olwandle, emoyeni, enhlabathini, njll. Insimbi engagqwali igqwala ngokushesha lapho kukhona ama-ion e-chloride kunensimbi evamile ethambile.

Ngakho-ke ukusetshenziswa kwemvelo yensimbi engenasici kunezidingo, futhi isidingo sokusula njalo, ukususa uthuli, ukugcina kuhlanzekile futhi komile.(Lokhu kumnika "ukusetshenziswa okungalungile.")

Kunesibonelo e-United States: inkampani yasebenzisa isitsha se-oki ukuze ibambe isixazululo esine-chloride ion.Isiqukathi sesisetshenziswe iminyaka engaphezu kwekhulu futhi kwakuhlelwe ukuthi sishintshwe ngeminyaka yawo-1990.Ngenxa yokuthi impahla ye-oki yayingeyona eyesimanje ngokwanele, isitsha sagqwala futhi savuza ezinsukwini ezingu-16 ngemva kokushintshwa ngensimbi engagqwali.

2. Akukho ukwelashwa kwesixazululo.

Izakhi ze-alloy azizange zincibilike ku-matrix, okubangele okuqukethwe kwe-alloy ephansi esakhiweni se-matrix kanye nokumelana nokugqwala okubi.

3. Izinto ezinjalo ezingenayo i-titanium ne-niobium zinokuthambekela kwemvelo kokugqwala kwe-intergranular.

Ukwengezwa kwe-titanium ne-niobium, kuhlanganiswe nokwelashwa okuzinzile, kunganciphisa ukugqwala kwe-intergranular.

Emoyeni noma kumakhemikhali okugqwala okuphakathi kungamelana nokugqwala kwensimbi ephezulu ye-alloy, insimbi engagqwali iyindawo enhle futhi imelana nokugqwala okuhle, akudingekile ukuthi icwecwe kanye nokunye ukwelashwa okungaphezulu, futhi idlale izakhiwo zemvelo zensimbi engagqwali, esetshenziswa izici eziningi zohlobo lwensimbi, ngokuvamile olubizwa ngokuthi insimbi engagqwali.Egameni lokusebenza kwensimbi ye-chromium engu-13, insimbi engu-18-8 chromium nickel kanye nenye insimbi ephezulu ye-alloy.

Ngokombono we-metallographic, ngenxa yokuthi insimbi engagqwali iqukethe i-chromium kanye nobuso bokwakheka kwefilimu encane kakhulu ye-chromium, ifilimu ihlukaniswe nomoya-mpilo ekuhlaselweni kwensimbi kokumelana nokugqwala.

Ukugcina ukumelana nokugqwala okukhona ensimbini engagqwali, insimbi kufanele ibe ne-chromium engaphezu kuka-12%.

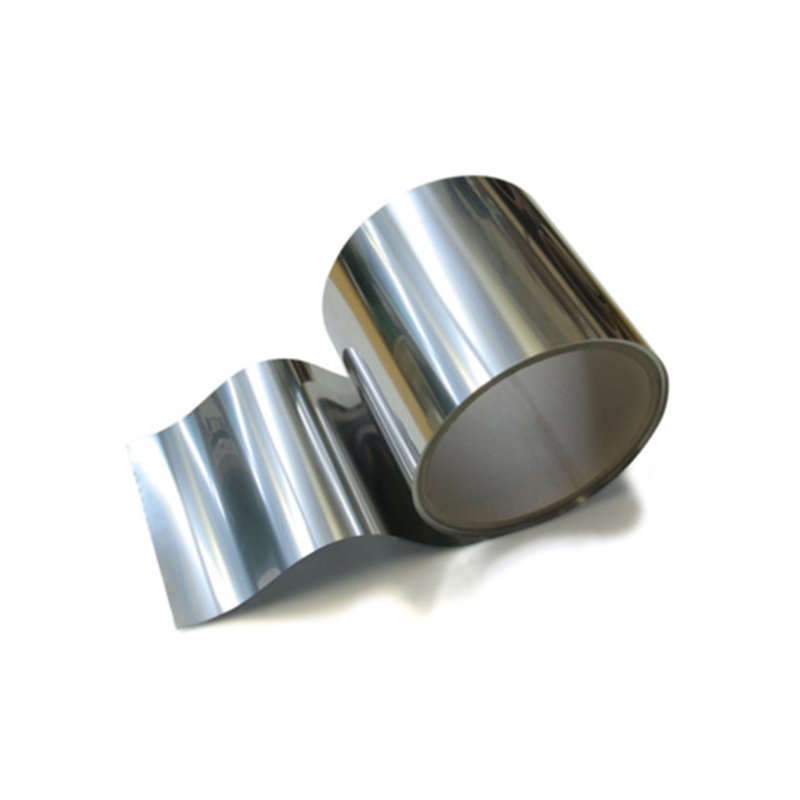

I-304stainless steel Shim Plates iyinsimbi engagqwali yendawo yonke, esetshenziswa kabanzi ekwenzeni izinto zokusebenza nezingxenye ezidinga izakhiwo ezinhle eziphelele (ukumelana nokugqwala nokubumbeka).

I-304 insimbi engagqwali iwuphawu lwensimbi engagqwali ekhiqizwa ngokuhambisana nezindinganiso ze-ASTM e-United States.I-304 ilingana ne-China 0Cr19Ni9 (0Cr18Ni9) yensimbi engagqwali.I-304 iqukethe u-19% we-chromium kanye ne-nickel engu-9%.

I-304 iyinsimbi engenasici/ekwazi ukumelana nokushisa esetshenziswa kakhulu.Isetshenziswa emishinini yokukhiqiza ukudla/imishini yamakhemikhali e-xiton/amandla enuzi, njll.

I-304 ihambisana nomkhiqizo waseShayina ongu-0Cr18Ni9,1Cr18Ni9Ti, okuqukethwe kwekhabhoni ≤0:08%

304Lstainless steel Shim Plates iwuhlobo lwe-304stainless steel Shim Plates insimbi engagqwali enokuqukethwe kwekhabhoni ephansi futhi isetshenziselwa izinhlelo zokushisela.Okuqukethwe kwekhabhoni ephansi kunciphisa imvula ye-carbides endaweni ethinteke ukushisa eduze nendawo yokushisela, okungaholela ekugqwaleni kwe-intergranular (ukuguguleka kwe-welding) kunsimbi engagqwali kwezinye izindawo.

Amapharamitha

| T | ubulukhuni | ubulukhuni | Isimo sokwelashwa kokushisa siqina imvula | conductive% | ||||||

| ubulukhuni | ubulukhuni | Amandla esivunoN/mm | Amandla okubambaN/mm | elongation% | Ukwelashwa kokushisa | ubulukhuniHV | Amandla esivunoN/mm | Amandla okubambaN/mm | ||

| 301-CSP | 1/2H | 340±30 | ≥510 | ≥930 | ≥10 | - | - | - | - | 2.3 |

| 3/4H | 400±30 | ≥745 | ≥1130 | ≥5 | - | - | - | - | 2.3 | |

| H | 460±30 | ≥1030 | ≥1320 | - | - | - | - | - | 2.3 | |

| EH | 510±20 | ≥1275 | ≥1570 | - | - | - | - | - | 2.3 | |

| SEH | ≥530 | ≥1450 | ≥1740 | - | - | - | - | - | 2.3 | |

| 304-CSP | 1/2H | 280±30 | ≥470 | ≥780 | ≥6 | - | - | - | - | 2.3 |

| 3/4H | 340±30 | ≥665 | ≥930 | ≥3 | - | - | - | - | 2.3 | |

| H | ≥370 | ≥880 | ≥1130 | - | - | - | - | - | 2.3 | |

| 631-CSP | 0 | ≤200 | - | ≤1030 | ≥20 | I-TH1050RH950 | ≥345≥392 | ≥960≥1030 | ≥1140≥1230 | 2.3 |

| 1/2H | 375±25 | - | ≥1080 | ≥5 | CH | ≥380 | ≥880 | ≥1230 | 2.3 | |

| 3/4H | 425±25 | - | ≥1180 | CH | ≥450 | ≥1080 | ≥1420 | 2.3 | ||

| H | ≥450 | - | ≥1420 | CH | ≥530 | ≥1320 | ≥1720 | 2.3 | ||